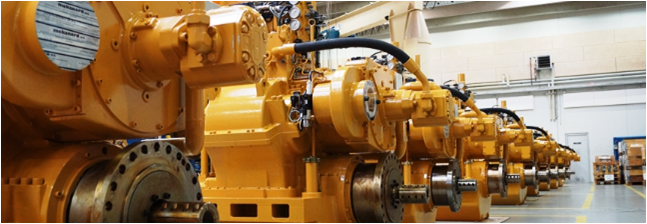

ME Production Marine Gearbox & CPP

Leading supplier of Marine gearboxes & CPP

Me Production the former brand name known as Mekanord, is a Danish market leader of Marine Reduction Gearboxes, Controllable Pitch Propulsion (CPP) systems and service solutions for marine gearboxes.

ME Production marine gearbox covers a power range from 150 KW to 10,000 KW with reduction ratios as high as 10:1, and CPP diameters up to 5 meters. Their gearboxes and CPP are suitable from small to large power rating marine engine.

ME Product design and manufacture marine gearboxes and deliver either the gearbox only or complete propulsion package including Controllable Pitch Propeller and Remote Control System. They aim to ensure maximum availability of the applications their customers operate.

ME Production has many years of experience within gearboxes and controllable pitch propulsion packages guarantee their customers the best solutions available. They continuously improve their products and are very particular to follow the leading market developments. This is the foundation of the high quality products, which they are known for.

ME Production Marine Gearbox and CPP System Features

- Completely integrated hydraulic servo system for pitch control which ensures easy installation, operation and maintenance.

- Compact design

- High reduction ratios available allowing large diameter, slow rotating propellers with high efficiency resulting in higher thrust and lower fuel consumption

- Up to 3 PTO’s available per gearbox – each with independent hydraulic clutch if required

- PTI for hybrid systems

- Customized gear ratios and PTO/PTI design

- Either mechanical or hydraulic operation of the propeller pitch

- Approvals according to latest rules from classification societies

The ME Productions marine gearbox product range covers a power range from 150 kW to 10,000 kW and includes specialties such as:

- HS = Built-in hydraulic servo gearbox

- OD = Gearbox prepared for oil distribution systems

- HSC = Compact gearbox for high speed vessels

- PTO = PTO gearbox

- Twin = Twin-in single-out twingear gearbox

- HS/LS= Gearbox with long stroke for sailing yachts

Advantages of ME Production CPP System

ME Production Controllable Pitch Marine Propulsion Systems offer a wide range of advantages. The most important are:

- Flexibility

- Efficiency

- Economy

- Maneuverability

A controllable pitch propulsion system ensures that the vessel will feature both maximum towing power and optimum speed. This is only possible using a controllable or variable pitch propulsion system. The CCP system technology ensures that it is always possible to achieve maximum engine efficiency regardless of the operation mode of the vessel. By adjusting the pitch propeller, the engine can operate at maximum power without overloading the system. At lower than maximum vessel speed, fuel consumption can be considerably reduced by lowering the engine RPM while increasing the propeller pitch to maintain the required vessel speed. In this way overall efficiency of the propulsion system is optimized.

The engine manufacturers use ME Production gearbox (Mekanord) included:

ABC, Caterpillar, Cummins, Detroit, GE, Mak, MAN, Mitsubishi, MTU, Scania, Volvo Penta, Wärtslia, Yanmar etc.…..

ME Production R&D department has the latest and most up-to-date design software at its disposal thus enabling them to carry out extensive calculations on all components either for repair, remanufacturing or a complete redesigned solution.

For details, please see the below Gearbox Selection Guide.

ME production Gearbox Selection Guide English Version

ME production Gearbox Selection Guide Chinese Version

SPARE PARTS

Spare parts are manufactured in ME Production machining department or are provided by their well-equipped sub suppliers.

Please specify gear number, type of gearbox and item number(s) according to spare part drawing when contacting us.

Ordering of spare parts can be done in the normal opening hours of the sales department at enquiry@rstmarine.com.hk

If we receive your order before 11.00 am, normally we can delivery stock parts from Denmark about two working days.

MASSON Marine

Masson Marine products equip all kinds of vessels in work applications, such as Barges, Fishing Boats, Naval Ships, Supply Vessels, Ferries, Life Boats, Pilot Boats etc.…….

Masson Marine gearbox power ranges from 370 kW to 3,700 kW, with reduction ratios as high as 14:1, and propeller diameters up to 5 meters.

Countless possibilities of adaptation and of life and clutch-controlled PTO attachments make Masson Marine the one comprehensive solution for your marine propulsion system.

We are able to offer you complete propulsion solutions, not only for the propulsion of the ship itself, through controllable pitch propellers (CPP), fixed pitch propellers, or electrical azimuth thruster, but for driving pumps and generators, too, and all other auxiliary equipment (winches, compressors, etc.) as required.

The Masson Marine design department are equally able to supply a full propulsion package, thus facilitating the job of all parties, engine manufacturers and shipyards included - be it for new shipbuilding projects, repowering jobs or repair.

The Masson-Marine gearbox

All Masson Marine gearboxes are symmetric with respect to the direction of rotation; the output shaft may run in engine-wise direction or in counter-engine-wise direction in the ahead mode of the ship.

All MASSON transmissions can be adapted to CPP, i.e. be built as non-reversing clutch/de-clutch transmissions.

Options and Special Features

MASSON gearboxes have a reliable and steady hydraulic system, and strong casings machined with high precision. They are suitable for continuous heavy-duty operation.

As an optional equipment, MASSON can also supply the engine coupling, the propeller shaft coupling flange with registering coupling bolts, and SAE bell housings.

The terminal part of the propulsion system

Masson Marine design, build, and install the entire system constituting the propeller and its "carrier". The unit includes the propeller shaft, the nozzle (if applicable), as well as the stern tube. We also realize the complete assembly that is dedicated to the connection to the gearbox.

There are two types of propellers in the field of professionally used ships:

The controllable pitch propeller (CPP) or swivel blade propeller

The fixed pitch propeller

Each of these types has its pros and cons. For further information, please see the chapters below.

Advantages Of A Controllable Pitch Propeller

Among the advantages of a controllable pitch propeller, here are the major ones:

Higher propulsion efficiency than with a fixed pitch propeller, optimizing speed and bollard pull performances.

Better maneuverability: passing from "ahead" to "reverse" occurs smoothly and without dead time, simply through propeller pitch inversion. The very short response time while maintaining full power ensures higher safety for the ship and crew, and considerably reduces the stopping distance of the vessel.

More efficient use of the diesel engine: 100 % engine power remain available at the propeller in every situation (cruising, trawling, maneuvering, etc.) What is more, a CPP allows constant operation of the engine at its nominal speed, thereby reducing significantly the fuel consumption, maintenance cost, and clutch disc wear.

Advantage of power take-off drives fitted to the transmission

With the engine at constant speed, the clutch-type PTO can drive pumps (for instance) for on-board machinery. So-called "live" permanent-drive PTOs may move alternators. In this way, the power requirement, the cost, fuel consumption and space requirement of auxiliary engines can be cut down.

For details, please download Selection Guide -2016 Edition