THE SWITCH a Diesel Electric Propulsion Systems Manufacturer from Finland

THE SWITCH a Diesel Electric Propulsion Systems Manufacturer from Finland

About The Switch

The Switch has an installed base of over 13 GW of megawatt-class permanent magnet machine and power converter packages. The main focus areas are wind, marine and special industrial solutions.

Starting in 2006, The Switch reported net sales of EUR 39.8 million in 2015. The company employs approximately 200 persons. The Switch is headquartered in Helsinki, Finland. In July 2014 Japanese company Yaskawa merger and acquisition with The Switch and now became sole owner of the company. Now The Switch, now is a Yaskawa company. This merger and acquisition strategy gives The Switch a firm foundation to continue advancing the world with electrical drive trains. Yaskawa Electric Corporation is a world-leading provider of core technologies focused on motion control, robotics automation, and systems engineering

Since it was founded in 1915, Yaskawa Electric has provided motor applications, advancement of industrial automation, the creation of mechatronics and cutting-edge robotics. Yaskawa today employs over 10,000 persons globally in its core divisions. The company reported net sales of EUR 3.3 billion in 2015.

The Switch takes marine drives to the world

The Switch has just acquired Wartsila’s Norway-based marine power drives product range for megawatt-class applications, as this business unit fits into The Switch own long-term strategy to offer environmental energy solutions for marine.

Finland, November 1, 2016 – The Switch, a technology specialist of advanced drive trains, has closed the deal on Monday, October 31, to purchase Wartsila’s Norway-based marine power drives product range business for megawatt-class applications. Backed by Yaskawa, this acquisition will provide a solid platform for the operations to focus on developing its core competences together. The main goal of The Switch acquisition is to take advantage of the synergies that these two organizations can bring to one another, including a stronger machine and drive package offering, a broader product range and wider international market access. Included in the deal is the power drives manufacturing factory and state-of-the-art test center in Stord, Norway, as well as an R&D facility in Trondheim.

“The Switch aims to be a major player in the Marine Drive Business. The Switch already have a good position globally in marine. And now with this acquisition, they will have more products to sell to their customers and more know-how to apply them in state-of-the-art solutions for green shipping, which is the clear trend in the industry. Through Yaskawa, The Switch can also provide more customers with access to these proven top-of-the-line products in the global market.

The 1,000th power drive milestone achieved

The Switch Marine Drives Norway AS starts off by celebrating the assembly of its serial number 1,000 drive and is now opening up for business to the world.

More about The Switch Marine Drives Norway AS

The new operational unit for The Switch has vast experience in delivering drives for demanding marine and oil & gas applications. This business originally began 15 years ago to focus on R&D engineering and was owned by Aker Elektro. In 2005, it was acquired by Wartsila Norway AS. The Drives business currently employs about 20 persons of which the majority are R&D and project engineers. The product range of 690 V low-voltage drives extends from 500 kW up to 5.5 MW single motors and 10 MW dual motors and 6600 V high-voltage drives from 5 MW to 24 MW.

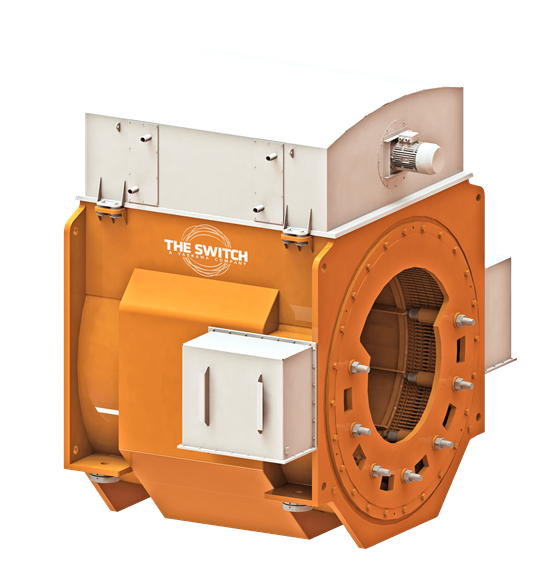

Permanent Magnet Technology

The Switch permanent magnet (PM) machines and frequency converters are game changers when it comes to reaching the highest energy efficiency, lowering the cost of operations and complying with future environmental legislation and safety regulations.

The PM machine can be used either as a generator or a motor.

Why a permanent magnet solution?

Why a permanent magnet solution? Higher efficiency

A PM machine gives high-efficiency performance over the entire operating range, significantly cutting back on fuel consumption. A PM machine is typically 2–4% more efficient at full load and 10% more efficient at part loads compared with induction machines. These efficiencies result from a lack of current losses in the rotor, the absence of an exciter and reduced winding losses.

High power density

The synchronous PM machine contains Neodymium-Iron-Boron (NdFeB) magnets, materials with a very high flux density, which makes them ideal for variable speed generators throughout the entire speed range. The magnetic field is created with almost zero losses.

Design flexibility

Thanks to the improved high density, a PM machine can be more compact, lighter in weight and smaller in size. This leads to greater flexibility with the limited space available in ship configurations.

Operational reliability

PM machines have proven their high reliability and durability under extremely harsh operating conditions in many industrial applications. They deliver excellent performance with corrosion resistance and temperature tolerance. With advanced thermal management, operational temperatures can be kept low, which in turn, assures an extended lifetime of the machine.

Widest range available

The Switch product portfolio of brushless PM synchronous machines is the widest in the market. The Switch offer drive trains from 1 MW to 10 MW at low, medium and high speed. The machines can be used either as a generator or as a motor.

The Switch PM machines comply with the standards of leading classification societies in the world. They have been tested, approved and certified to ensure highest possible reliability of the vessels and to comply with the strict international safety and environmental standards.

Marine data sheets:

Frequency Converter Superiorities

Optimized for best efficiency

The Switch frequency converter is based on insulated-gate bipolar transistors (IGBT) with advanced vector control technology. It is optimized to work with PM machines for the best overall system efficiency. The Switch converters offer a modular, lightweight design, which enables efficient use of space within the vessel.

Active front-end speed control

With active front-end (AFE) frequency drive technology, The Switch converter enables Power Take In (PTI) and Power Take Out (PTO) modes, while allowing a shaft generator to operate at variable speed. This technology enables the use of a PM machine to be operated as a motor or a generator according to the application requirement.

Liquid cooling and thermal management

The Switch frequency converter is designed with liquid cooling and exceptional thermal management. This results in a more compact size of the converter, which makes it easy to locate within limited vessel space.

Reliability in harshest conditions

The frequency converter features a rugged IP54-class panel. It is designed to be used in harsh environments, such as those on open sea. It is also easily accessible for installation and maintenance.

Shaft Generators

Game-changing drive trains for energy efficient power generation

Next generation drive trains based on permanent magnet (PM) technology from The Switch are game changers in their own right when it comes to reaching the highest energy efficiency and lowering the costs of operation. Additionally, they help comply with future environmental legislations. Solutions such as these enable ships to stay afloat and profit in the sea of fierce competition.

Permanent magnet machines – a special force for shaft generators

The shaft generator has been successfully used on board ships for the past 30 years. The main benefit of adding a shaft generator is to produce electrical power with the main engines that have lower fuel consumption and run on cheaper heavy fuel oil, thereby significantly reducing the use of auxiliary generators. The downside, however, is that the propulsion machinery can only be run at constant speed.

The other alternative has been to operate without a shaft generator. In this case, ships continue to take advantage of the main engine’s variable speed operation while auxiliary generators produce electricity on board. The downside is that the ship operator pays a premium in higher fuel cost as well as auxiliary generator maintenance costs.

Now merchant vessels can get the best of both worlds by using a game-changing solution that combines advanced control with The Switch PM machine and frequency converter technology. This enables vessels to produce electricity with better efficiency for the entire ship’s network, lower costs by keeping auxiliary generators off – and allow the main engines to operate at variable speed and generate electricity. In total, it represents major operational savings for vessels with 4-stroke, but in particular 2-stroke engines.

Next generation, electrical drive trains that lead to exceptional energy efficiency and lower operational costs are built from a PM motor and a frequency converter as the major components. The controller acts as the brains for energy efficiency, keeping the network stable regardless of external conditions, such as waves, speed and other influential factors.

Although a newcomer to the shipping industry, PM technology with its matchless design flexibility has reached unprecedented success in numerous other industries. Thanks to their higher power density, PM machines can be more compact, lighter in weight and smaller in size.

Game-changing solution for drive trains from The Switch

- PM machine:?provides unmatched power density, energy efficiency, design flexibility and operational reliability

- Frequency converter:?robust and liquid cooled

- Control:?the brains for energy efficiency

- Take me home / boost mode:?enables use of auxiliary generators and/or batteries

- DC-link: brings energy efficiency to the entire vessel

PM technology for unmatched power density

PM technology has been proven in numerous industries to provide energy efficiency, high power density, design flexibility and operational reliability. Now these same advantages are available for numerous marine applications.

Energy efficiency

A PM machine gives high-efficiency performance over the entire operating range, significantly cutting back on fuel consumption. A PM machine is typically 2-4% more efficient at full load and 10% more efficient at part loads compared with induction machines. These efficiencies result from a lack of current losses in the rotor, the absence of an exciter, and reduced winding losses.

High power density

A synchronous PM machine contains Neodymium-Iron-Boron (NdFeB) magnets, materials with a very high flux density, which makes them ideal for variable speed generators throughout the entire speed range. The magnetic field is created with almost zero rotor losses.

Design flexibility

Thanks to the improved high density, the size and weight of a PM machine can be substantially reduced. This leads to greater flexibility with the limited space available in ship configurations.

Operational reliability

PM machines have proven their high reliability and durability under extremely harsh operating conditions in many industrial applications. They deliver excellent performance with corrosion resistance and temperature tolerance.

All-new opportunity for merchant ships

The combination of The Switch PM and frequency converter technology opens up all-new opportunities for hybrid propulsion systems, namely in the large merchant shipping sector, where 2-stroke main engines are the preferred type of prime mover.

Ocean-going merchant vessels are predominantly propelled by fixed pitch propellers that are directly driven from slow-speed, 2 -stroke main engines. Along with being very reliable, the 2-stroke main engine is also able to keep fuel consumption at least 20 g/kWh lower compared with a medium speed 4-stroke main engine.

As a merchant vessel sails long distances in the deep sea during most of its operating time, fuel economy is the most important factor after safety and reliability. The 2-stroke main engine operates on slow speeds, equivalent to the required propeller speeds. Therefore, this type of engine is directly connected to the propeller via an intermediate shaft, requiring no additional gearing to match the required revolutions. This leads to a more straightforward propulsion system with fewer components.

Traditionally, adding a shaft generator to this system required special equipment, such as tunnel gears with a step-up PTO shaft for the generator drive. These arrangements add complexity to the system and are fairly costly. A direct-drive PM shaft generator with a variable frequency drive offers the advantages of a hybrid propulsion system to the 2-stroke main engine driven propulsion system.

In the direct-drive PM shaft generator, the rotor is mounted on the intermediate shaft of the propulsion system. Mass and inertia are very low and thus the impact on propulsion system torsional vibration calculations (TVC) remains minimal. No additional bearings are required, thus the propeller shaft system design remains uncompromised.

Up to €50,000 per month in fuel savings

Advantages for these large merchant vessels include energy efficiency and lower operational costs. First, the new drive train enables electrical production with the main engine, which provides much greater energy efficiency than with the auxiliary generator. Second, it can use heavy fuel oil or liquefied natural gas (LNG) as fuel, which are much cheaper fuel sources than the marine diesel oil used by auxiliary generators.

And finally, from an electrical perspective, a solution from The Switch can be dimensioned to allow ships to operate in a combination mode of a controllable pitch, angle and speed. This ensures that the ships can run in the most efficient way with the best available technology.

In terms of actual numbers, merchant ships can save up to 50% in energy consumption by lowering their speeds by 4 knots. Running the ship at lower speeds also requires less maintenance. Moreover, by adding the latest technology, a ship owner can save up to €50,000 per month in fuel costs, which may add up to 7% more profit per year.

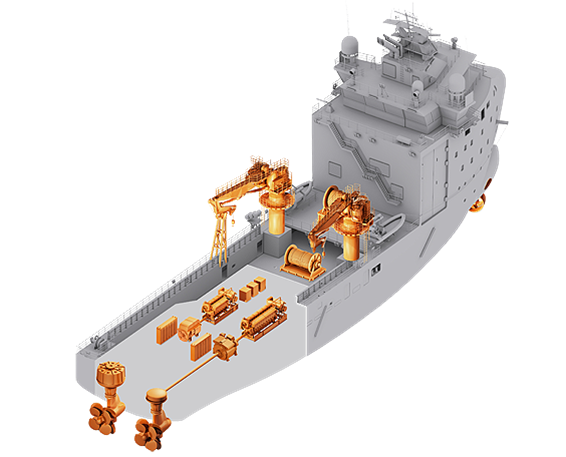

Electric Propulsion

In electric propulsion, The Switch offers special seafaring vessels, like ferries, cruise lines, tugboats and icebreakers, the opportunity to take advantage of lower operational costs by optimizing the fuel consumption of the diesel engine.

Game-changing drive trains for energy efficient power generation

As cost pressures mount and environmental regulations become more stringent, the need for a novel and smarter approach is becoming ever more apparent. This is especially the case for multipurpose service vessels that operate primarily at partial load conditions. Instead of just tweaking conventional technology, such as induction motors, to try and invent a better solution, results prove that there’s a much better way to save on operational costs.

Using permanent magnet (PM) motors and generators as key elements in advanced drive trains allows ship owners to take advantage of a more flexible, modular, efficient and lightweight propulsion system.

Although new to marine applications, PM technology has in fact been a game changer for many years in other industries, such as wind power, where it ensures the highest energy efficiency and lowest costs of operation. As a bonus, this technology helps future-proof ships when it comes to even the strictest environmental legislation.

Switch to permanent performance at sea

For electric propulsion, PM technology based solutions are ideal for seafaring vessels, such as ferries, cruise lines, tugboats, offshore, research vessels, icebreakers and more. The technology enables ships to lower their operational costs by optimizing fuel consumption through superior efficiency, reliability and design flexibility.

Higher system efficiency

A synchronous PM machine contains Neodymium-Iron-Boron (NdFeB) magnets, which are materials with a very high flux density. This makes them ideal for variable speed motors and generators throughout the entire speed range. The magnet field is created with almost zero rotor losses.

More power

A PM machine gives high-efficiency performance over the entire operating range, significantly cutting back on fuel consumption. The PM machine is typically 2–4% more efficient at full load and 10% more efficient at part load when compared with induction machines. These efficiencies result from a lack of current losses in the rotor, the absence of an exciter, and reduced winding losses.

PM propulsion motors and their inverters efficiently turn available energy into thrust. Although standard induction motors can reach good efficiency in a narrow band around their nominal working area, PM motors are designed to deliver even higher efficiency in a much wider speed and torque range. This is crucial to cutting back on total fuel usage.

Lower fuel consumption

In a recent study of two 1250 kW diesel-electric propulsion trains, PM motors achieved an annual fuel savings of >3% with the same Z-drive thruster. PM motors also make it possible to use an L-drive thruster, which results in fuel savings by an extra >1%, along with length and weight savings thanks to the stacking ability.

Better, adjustable speed control

A frequency converter offers the accurate and adjustable speed control needed for dynamic positioning and demanding load cycles in offshore and special vessels. The high energy density of PM technology and resulting lower rotor inertia are beneficial when the ship needs high maneuverability and a DP class propulsion system. This results in optimum fuel efficiency and lower levels of exhaust.

Highly pulsating power demand also poses a serious threat to the lifetime of a vessel’s engine. The ability to deliver to a combination of short full-power bursts and longer low-power demands is extremely wearing.

To handle highly fluctuating load cycles, guarantee longer engine life, cut back on fuel consumption and reach lower exhaust values, adjustable speed control is ideal. This avoids the low or no-load running of generators, which minimizes engine heat stress, reduces fuel consumption and eliminates undesired start/stop engine cycles.

Reliability

PM machines have proven their high reliability and durability under extremely harsh operating conditions in many industrial applications. For example, they have even been used in wind turbines, which operate in a much harsher environment than the challenging marine market.

Fewer failures, less maintenance

In direct propulsion systems, no gearbox or accompanying slip rings and brushes are needed, as with other synchronous machines. Therefore, the PM propulsion line machine experiences fewer failures and requires significantly less maintenance.

Modular, design flexibility

PM solutions are compact, with lower weight and volume than conventional drive trains. They offer unsurpassed flexibility and a smaller footprint for all types of configurations, especially when space is a critical factor. Additionally, PM solutions comply with low environmental footprint requirements.

By using a PM generator as part of a genset, significant weight savings can be achieved, and the total length of the genset can be reduced. On the propulsion side, using a PM machine as a propulsion motor combined with an inverter can lead to weight savings and switchboard length reductions.

In all, this radically changes a typically packed machine room into an easily accessible space for machines, crew and maintenance personnel.

Frequency converters

The Switch frequency converters are optimized to work with PM machines for the best overall system efficiency. The electricity produced is of better quality with low flicker, reduced electrical noise emission and THD <1.5%. Additionally, PM drive trains have always demonstrated superior grid connection behavior, even in distributed environment.

The frequency converter features a rugged IP54-class cabinet, which is a higher class to withstand the harsh sea environments. It can be easily accessed for installation and maintenance.

For more information about The Switch product, please contact us at enquiry@rstmarine.com.hk